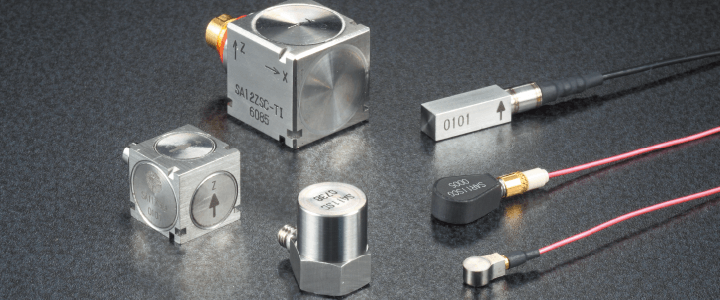

Accelerometers

Description:

The measurement of acceleration, velocity and displacement can be used to measure vibration. Of these methods, piezoelectric accelerometers are the most widely used sensors in the fields of vibration and shock instrumentation.

-

Introduction

Download a PDF Version

-

Charge output accelerometers

- fc is determined by capacitance and amp’s input impedance. fc=1/2πRC

- Value includes capacitance of low-noise cable(with a 2-meter cable for connector-type sensors)

Charge output accelerometers

-

Voltage output accelerometers

Voltage output accelerometers (built-in pre-amplifier)

-

Industrial accelerometers

Industrial accelerometers for machine monitoring

(Waterproof and insulated)

-

Triaxial accelerometers

Charge output type

- fc is determined by capacitance and amp’s input impedance. fc=1/2

- RC

- Value includes capacitance of low-noise cable(with a 2-meter cable for connector-type sensors)

Voltage output type (built-in pre-amplifier)

- Transducer Electronic Data Sheet (IEEE1451.4 Template Ver.1.0)

-

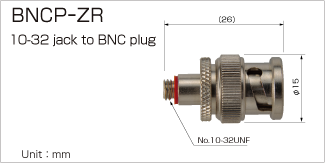

Cable & Connector

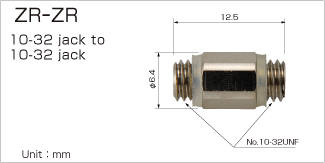

- Miniature=10-32 plug

- Max. temperature of BNC part is 60 to 80℃

Exclusive use cable

- Max. temperature of BNC part is 60 to 80℃

Cable Selection guide

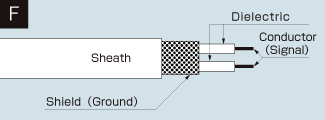

Usually, a charge output accelerometer is used with a low-noise cable, and a preamplifier-built-in sensor is used with a coaxial cable. Select a suitable cable, taking into account the environment-related performance of the cables.

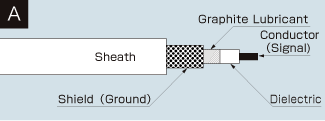

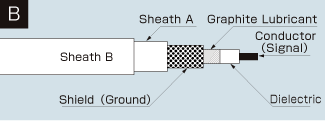

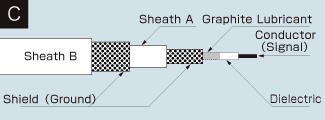

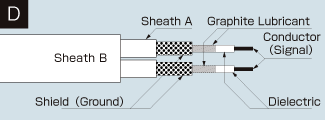

Structure of cable

Low-noise cable has graphite lubricant to reduce noise with capacitance variation occurred by bending or distortion(A ~ D)

Reference Data on Cable Materials

Use these data when you select a suitable cable.

Connector

-

Mounting Adapter

We offer various range of mounting adapters. Use the adapter best suited to your intended application, and give careful consideration to the influence on the sensor’s frequency characteristics.

Note:Check the screw size before placing an order.Magnetic holders

The magnetic holder attaches easily to the surface of objects that have magnetic properties, and is very useful if you want to move your sensor from one place to another without permanently mounting it. Our magnetic holders will not adversely affect the high frequency of our accelerometers.

【Caution】Our magnetic holders are powerful; if you slap the holder onto a surface even from a distance of 10 mm away, the magnetic attraction will be so strong that the holder will slam onto the metal and subject the sensor to an acceleration shock of 10,000m/s2 or greater that may damage the sensor. Once the edge of the holder touches the surface, keep your hand on the holder and lower it gently into place.

Insulation studs

Insulation studs are generally used for measurements of motors that emit high-level electric noise. The insulation between the sensor and the object surface prevents ground loop noise from entering.

【Caution】Applying excessive tightening torque may cause damage to the bonded portions of the insulation stud. Attach insulation studs with standard tightening torque.

Mount base for triaxial cubic sensor

Expendable bonding mount for cubic sensor

- Material: ABS One pack contains 5 pieces.

- Sensors adapted: ⑪SA11ZSCA, SA12ZSCA, 3511A2, 3512A2

- Sensors adapted: ⑫SA11ZSC-TI, SA12ZSC-TI, 3511A1, 3512A1

Bonding studs

Bonding studs eliminate the need to apply adhesive directly to the sensor and risk blocking or fouling the screw holes. Bonding studs are attached to the subject by cyanoacry late instant adhesive, or other adhesive.

Screw conversion studs

These are used in cases where the subject’s screw tap and the accelerometer’s screw do not match one another.

Heat-insulating stud

This stud is used to block the conduction of heat from the subject to the accelerometer; however, please be aware of radiant heat, convection and heat conduction effects.

Hand probe

Used when taking readings of locations too confined to permit the mounting of an accelerometer.

-

Charge converter & Power supply

Charge converters

Charge converters convert the high-impedance electric charge output signal of piezoelectric accelerometers into low-impedance voltage signals.These are line drive pre-amplifiers that enable the sensor output signal to connect to the measuring devices. The price is much lower, compared with ordinary charge amplifiers.

Constant current power supplies

The CCPS-3 is line-drive constant current power supply for charge converters and accelerometers that have built-in amplifiers. CCPS-3A:0.1~50,000Hz ± 1dB

CCPS-3A:0.1~50,000Hz ± 1dB

-

Sensitivity calibrator

Mini calibrator MC-20

The MC-20 directly calibrates accelerometers, on site

Piezoelectric accelerometers are widely used to analyze vibrations and diagnose the performance of rotating machinery. Checking the sensitivity of accelerometers after they have been used under harsh conditions or for a long time has usually been left to the manufacturers because of the expensive calibration equipment required.

The MC-20 integrated the exciter, amplifier and display in a single unit.All you have to do is attach the sensor, for a speedy calibration of the sensor’s sensitivity. You will now be able to gather reliable data with confidence, any time that you need to.

• Up to 100 data can be stored in the unit of MC-20.(Sensitivity, DC bias voltage, date and time)

• Data can be transferred to PC.

• Powered by batteries or AC cable.Example of calibrator in use

(Example.1)

Directly input the sensor output, and check the sensitivity.

(Example.2)

Use the exciter only, and calibrate the vibration measuring system. -

Calibration

Accelerometer traceabilityTo ensure that our sensors are in the best condition when you use them, we conduct strict quality control that guarantees sensor traceability with the national standard. In our calibration system, transfer standard sensors are calibrated once a year by a laser interference method; normal standard sensors are calibrated once every two months by a comparison method.

![Fuji Ceramics' calibration method[Comparison method]](http://www.fujicera.co.jp/managed/wp-content/themes/fujicera/images/product/sensor/acceleration/en/img_calibration_01.png)

Calibration Certificate

Fuji Ceramics delivers each accelerometer with its own outgoing inspection sheet. This sheet includes the sensor’s serial number, sensitivity, insulation resistance, and a chart of the sensor’s frequency characteristics in the range from 100 Hz to 60 kHz.- If required, a chart of the frequency range 1 Hz to 100 Hz can be supplied as a separate option.

- In the case of tri-axial accelerometers, the chart represents the Z axis only.

- It is preparing English, too.

Traceability Calibration Guarantee Certificate (Japanese only)

If you require a Traceability Calibration Guarantee Certificate when you wish to send an accelerometer away to be calibrated, please ask us for a Certificate in advance. We will issue a Traceability Calibration Guarantee Certificate that will include a calibration certificate of the calibrator used to calibrate your sensor. Generally, when we perform a periodic calibration of your accelerometer, we will only supply a Outgoing Inspection Sheet.