Drivetrain Prognostics Simulator

Our Best Tool for Drivetrain Prognostics Research

Description:

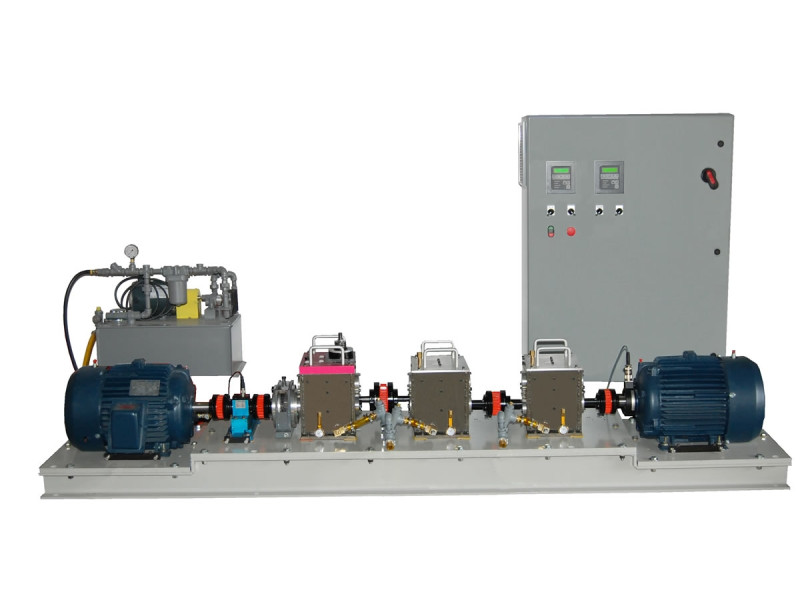

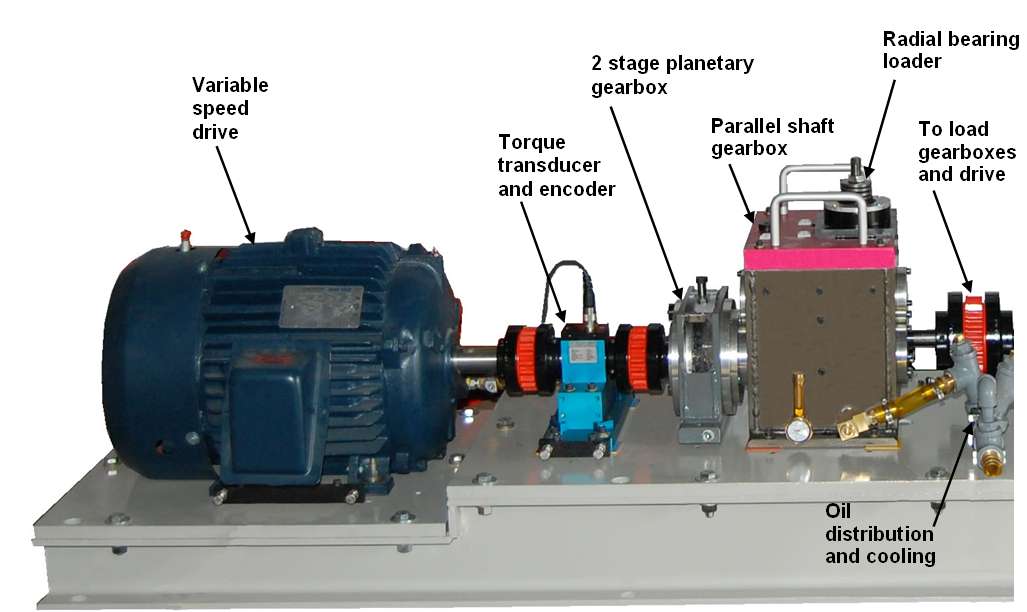

SpectraQuest’s Drivetrain Prognostics Simulator (DPS) has been specifically designed to simulate industrial drivetrains for diagnostics and prognostics research. The DPS drivetrain consists of a two-stage planetary test gearbox and a two-stage parallel shaft test gearbox with rolling or sleeve bearings. These two test gearboxes can be arranged to apply the highest torque to either, a torque which is large enough to induce wear and damage in the gears. The two-stage parallel shaft gearbox can be configured with a gear ratio from 1 to 6. All elements of the DPS have been designed to maximize the number of drivetrain configurations to investigate gearbox dynamics and acoustic behavior, health monitoring, and vibration based diagnostic and prognostics techniques. It is robust enough to handle heady loads and spacious enough for easy gear placement, setup, and installation of monitoring devices. The two test gearboxes are attached to two parallel shaft load gearboxes and drive.

-

Why DPS

Gear and Bearing Fault Diagnostics and Prognostics

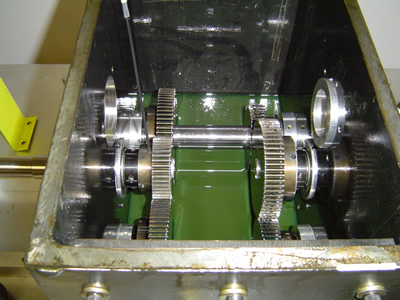

The effect faults like surface wear, crack tooth, chipped tooth and missing tooth can be demonstrated and induced on either spur gears or helical gears. Rolling element bearing faults like inner race, outer race, and ball damage can also be incorporated. Adjustable clearance to study backlash is possible: increasing the amount of backlash is without major consequence, and reducing backlash can result in binding and/or excessive operating temperatures. Drivetrain misalignment can also be introduced intentionally in the DPS. Any of these faults can be added to the drivetrain one at a time, or simultaneously to study fault interactions. Both torsional and radial loadings can be applied to study damage signature or propagation in gears and/or bearings: the torsional load is applied via a 10 HP variable frequency AC drive with a programmable, user-defined speed profiles; and the radial load is applied to a shaft in the parallel gearbox. With the programmable load drive, load fluctuations can be applied to simulate real life loading conditions.

-

Features

Features

• One 2-stage planetary test gearbox 27:1 ratio.

• One 2-stage oil-lubricated parallel shaft test gearbox up to 6.25 ratio.

• Planetary and parallel shaft gearboxes re-locatable to induce damage in either test gearboxes.

• Torsional and radial variable speed loading.

• Gears can slide along the parallel shafts to alter system stiffness and make room for additional devices.

• Parallel shaft gearbox adaptable to spur or helical gears and to rolling element bearings or sleeve bearings.

• Intentionally damaged or worn gearing can be fitted to study the effects on vibration signature.

• Alterable backlash by replacing bearing mounting hubs to provide the desired clearance.

• Modular design makes the introduction of faulted bearing and/or faulted gears an easy task.

• Load drivetrain consist of one 3-stage and one 2-stage oil-lubricated parallel shaft gearboxes providing up 98:1 ratio.

• Multiple mounting locations provided for installation of various transducers.

• Develop diagnosis and prognosis techniques and advanced

The DPS is Heavy-Duty and Easily Configurable

The DPS design enables changing gearbox and bearing components quickly and easily. The parallel gearbox is adaptable to install either rolling element bearings or oil-impregnated sleeve bearings with either spur or helical gears. The modular design makes the introduction of faulted bearing and/or faulted gears an easy task.

Transducers and DAQ

The drivetrain is designed to accommodate different types of sensors easily. Accelerometers can be installed on the gearboxes and on the bearing housing to measure the vibrations in all three directions. A torque meter enables precise load measurement. The input and output shafts can be fitted with encoder or tachometer to measure the transmission error or for time synchronize averaging. Other transducers can also be installed per customers’ request. Data acquisition hardware and software are also available from Spectra Quest and ready to do time domain and frequency domain signal analysis.

-

Specifications

Electrical Motor

3 Phase, 10 HP motor

Drive 3 Phase, 10 HP motor

RPM Range

10 HP variable frequency, common bus AC drive system with multi-featured front panel programmable controller

Tachometer 0 to 3600 rpm variable speed

Voltage 230 VAC, Three phase, 60/50 Hz

Mechanical

Shaft Diameter 1″ diameter; Turned, Ground, & Polished (TGP) steel

Test Planetary Gearbox 2-stage, 27:1 gear ratio planetary gear with 4 planet stage1 and 3 planet stage 2

Test Parallel Gearbox 2-stage, 2.5 maximum ratio per stage (6.25 max), spur or helical gears Test Parallel Shaft Gearbox Bearing Deep groove ball bearing or oil-impregnated bronze sleeve bearing Test Bearing Loader 3000lb capacity with force transducer Load Gearboxes 98:1 total maximum ratio

One 2-stage, 2.5 maximum ratio per stage (6.25 max), spur gears

One 3-stage, 2.5 maximum ratio per stage (15.6 max), spur gears

Deep groove ball bearingTorque meter Up to 100N.m with built-in 360 pulse encoder Output shaft encoder 360 pulse per turn encoder Alignment Jack bolts on gearboxes and motors for horizontal alignment Oil Distribution 0.9 gpm capacity distribution and cooling oil system driven by 1/3 HP motor Foundation 5/8″ steel plates on 4″x6″ steel beams Physical

Weight Approximately 2200lb (1000kg) Dimensions L=39″ (100cm), W=20″(50cm), H=24″ (60cm)

L=30″ (76cm), W=16″ (41cm), H=26″ (66cm) oil distribution

D=17″ (43cm), W=36″ (91cm), H=60″ (152cm) motor drive

-

Basic DPS

Basic Drivetrain Prognostics Simulator System includes:

• Two 3 Phase 15 HP heavy duty induction motors, one to drive and one to load test gearboxes

• Two 15 HP variable frequency drives, common DC bus drive system with multi-featured front panel programmable controller

• Test Gearboxes:

• One 2-stage planetary gear with four planet stage 1 and three planet stage 2

• One in-line parallel shaft gearbox configurable as two stage reduction/increaser,

• Load Gearboxes:

• Two in-line parallel shaft gearbox with much larger load capacity than test gearboxes; one gearbox with two stage increaser, one gearbox with three stage speed increase

• Ten spur gears between to two gearboxes giving sevral mesh frequencies

• Fourteen rolling element bearings

• Precision machined bearing housings at both ends of the gearbox with mountings for direct measurements of bearing vibration

• Gearbox bearing loader (4000lb capacity) with force transducer mounted on parallel shaft test gearbox

• Jack bolts on gearboxes and motors for horizontal alignment and standard shims for vertical alignment

• Input shaft torquemeter (up to 100N.m) with built-in 360 pulse encoder

• Output shaft of the test gearbox with 360 pulse per turn encoder

• Gearbox oil level gauge

• 0.9gpm capacity distribution and cooling oil lubrication system driven by 1/3HP motor

• Vibration isolators mounts and base stiffener

• Comprehensive operations manual

-

Option Kits

The DPS provides a basic setup for performing drivetrain diagnosis and prognosis experiments. SpectraQuest also offers pre-damaged gears for in-depth study and parallel gearbox conversion kits to helical gear and sleeve bearings. -

Package

High Value Combination Packages

The DPS is available in high value combination packages focusing on bearing and gear studies.

Package # 1 : Basic DPS + Kits for in-depth studies of bearing and gear diagnostics concepts

Option kit

PKG 1

Parallel gearbox bearing fault kit G-BFK-1 x Planetary Gearbox Bearing Fault Kit G-BFK-P x Parallel gearbox oil-impregnated sleeve bearing G-SBH x Defective spur gears G-SDG x Eccentric Spur Gear G-ESG x Helical gears set G-HG x Defective helical gears G-HDG x Defective planetary gears G-PDG x PC Motor and Load Control Kit G-PCMLK x