Gearbox Dynamics Simulator

An Ideal Simulator For Gearbox Reliability Studies

Description:

Gearbox Dynamics Simulator (GDS) has been specifically designed to simulate industrial gearbox for experimental and educational purposes. The gearbox consists of a 2 stage parallel shaft gearbox with rolling bearings and a magnetic brake. All elements of the GDS have been designed to investigate gearbox dynamics and acoustic behavior, health monitoring, vibration based diagnostic techniques, lubricant conditioning or wear particle analysis. It is robust enough to handle heady loads and spacious enough for easy gear placement, setup, and installation of monitoring devices. The two-stage parallel shaft gearbox can be configured as to reduce or increase the gear ratio.-

Features

Features

• Portable, robust, cost-effective balance and bearing vibration trainer.

• Ideal for teaching multi-plane balancing with centerhung / overhung rotors.

• Can be setup to exhibit bearing fault frequencies both further away from, and closer to multiples of the shaft rotational speed

• Develop signal processing techniques to identify bearing fault frequencies in the presence of defects, at multiples of shaft speed, without using high-resolution spectra

• Use the GDS to recognize the vibration spectra of different bearing faults.

• 11 different application specific study kits available

Flexible Gearbox Fault Diagnostics

The effect faults like surface wear, crack tooth, chipped tooth and missing tooth can be demonstrated on either spur gears or helical gears. Rolling element bearing faults like inner race, outer race, ball damage can also be incorporated. Adjustable clearance to study backlash is possible: increasing the amount of backlash is without major consequence (other than increased noise and rotational play), and reducing backlash can result in binding and/or excessive operating temperatures. Any of these faults can be added to the gearbox one at a time, or simultaneously to study fault interactions. Torsional can be applied via a 3 HP variable frequency AC drive with a programmable, user-defined speed profiles, to study damage signature or propagation in gears.

The GDS is Easily Configurable

The GDS design enables changing gearbox and bearing components quickly and easily. The unit is adaptable to install either spur or helical gears. The modular design makes the introduction of faulted gears an easy task. Multiple mounting locations are provided for installation of transducers. The motor, gearboxes, brake are mounted on a half inch aluminum plate with stiffeners and vibration isolators to minimize environmental vibration. -

Specifications

Electrical Motor

3 Phase, 3 HP motor, pre-wired self-aligning mounting system for easy installation/removal

Drive 3 HP variable frequency AC drive with multi-featured front panel programmable controller

RPM Range

0 to 5000 rpm variable speed

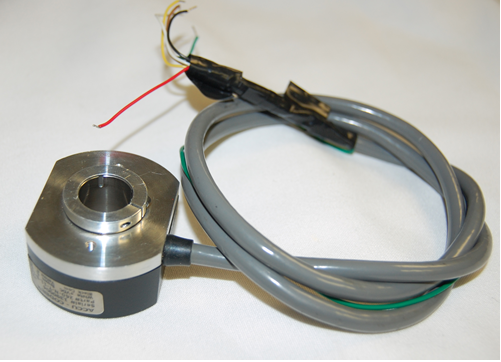

Tachometer Built-in tachometer with LCD display and one pulse per revolution analog TTL output for DAQ purposes

Voltage 230 VAC, Three phase, 60/50 Hz

Mechanical Shaft Diameter 1″ diameter; Turned, Ground, & Polished (TGP) steel Parallel Gearbox 2 stage, 2.5 maximum ratio per stage, spur or helical gears Gearbox Bearing Deep groove ball bearing or oil-impregnated bronze sleeve bearing Magnetic Brake 4-220 lb.in capacity magnetic particle brake Foundation 1/2″ (12.7 mm) die cast aluminum base, base stiffener and eight rubber isolators Physical Weight Approximately 200 lb Dimensions L=39″ (100cm), W=20″(50cm), H=24″ (60cm) -

Basic GDS

Basic Gearbox Dynamics Simulator System includes:

• 3 HP Variable frequency AC drive with multi-featured front panel programmable controller, 220 VAC 1 phase supply

• 3 Phase 3 HP motor, pre-wired self-aligning mounting system for easy installation/removal

• Three in-line parallel shafts configurable as single or two stage reduction/increaser

• Four Spur Gears to obtain two gear mesh frequencies and three shaft speeds

• Built-in Tachometer with LCD Display and analog output for DAQ purposes

• Six rolling element bearings

• Programmable Magnetic brake (220lb-in) with power supply for gearbox loading

• Precision machined bearing housings at both ends of the gearbox with mountings for direct measurements of bearing vibration

• Gearbox oil level gauge

• Vibration isolators mounts and base stiffener

• Comprehensive operations manual -

Option Kits

The GDS Provides a basic setup for performing gearbox experiments and for learning vibration signatures of gearbox and bearing malfunctions.However.a detailed investigation of particular and more advance vibration phenomena will acquire additional attachments and fixtures which are available through optional kits.

-

Packages

High Value Combination Packages

The GDS is available in two High Value combination packages providing you with up to 6% savings.

Package # 1 : Basic GDS+ Kits for in-depth studies of gearing concepts

Package # 2 : Basic GDS+ Kits in-depth studies of gearing concepts and motor diagnostics with instrumentationOption Kit

PKG 1 PKG 2 Bearing Fault Kit G-BFK-1 X X Defective spur gears G-SDG X X Eccentric spur gear G-HG X X Helical gears set G-HDG X X Defective helical gears G-ESG X X PC motor control kit G-PCMK X X PC Load Control Kit G-PCLK X X 1 HP AC motor with built-in rotor unbalance G-UBM-1 X 1 HP AC motor with built-in rotor misalignment system G-MAM-1 X 1 HP AC motor with built-in bowed rotor G-BRM-1 X 1 HP AC motor with built-in faulted bearings G-FBM-1 X 1 HP AC motor with built-in broken rotor bars G-BRBM-1 X 1 HP AC motor with stator winding faults G-SSTM-1 X 1 HP AC motor with voltage unbalance & single phasing G-VUSM-1 X -

Downloads