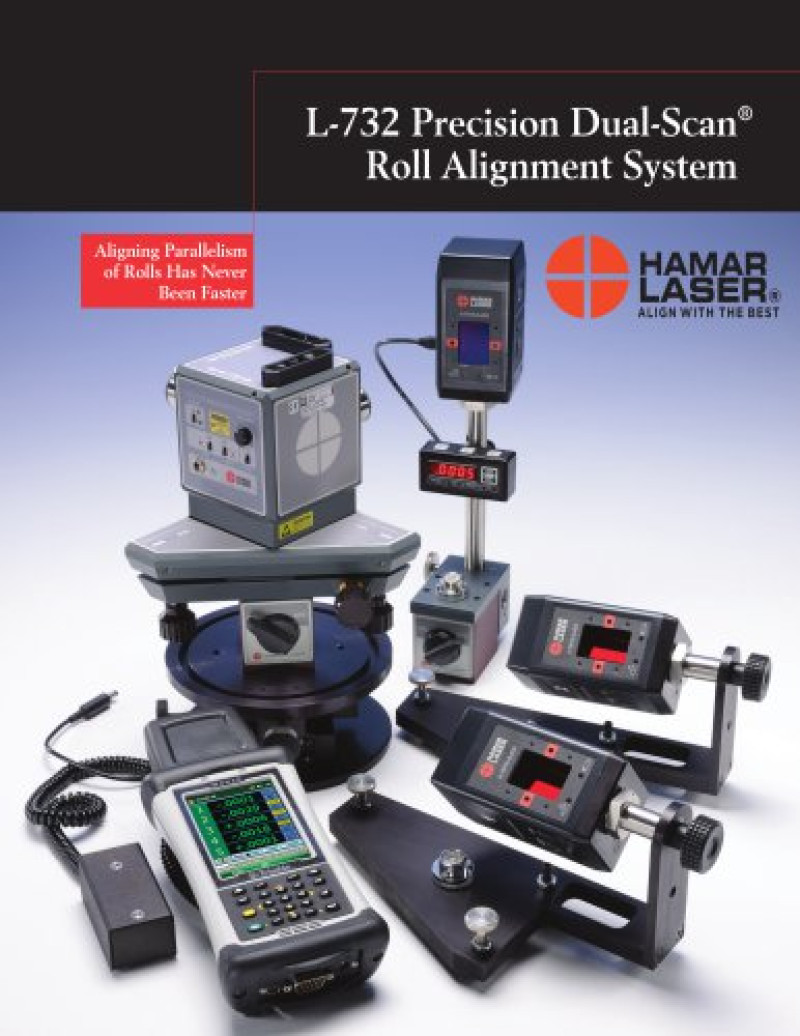

L-732 Precision Dual Scan® Laser

Description:

Hamar Laser’s L-732 Precision Dual Scan® Laser Alignment System is designed for quickly and accurately aligning all types of machinery with rolls, such as roll-forming machines, film lines and printing presses, as well as several other similar applications, where the required accuracy is a lot lower than that of our L-742 Ultra-Precision Laser. The L-732 can be configured by the factory to have either 2 vertical laser planes (the typical configuration for roll alignment), or 1 horizontal and 1 vertical laser plane (for measuring flatness, straightness and squareness of surfaces and lower-accuracy machine axes). This creates a powerful tool that not only measures alignment, but also re-aligns machinery in a fraction of the time needed with conventional methods.

System Highlights

- Fast: Aligns roll-forming machinery and other roll alignment applications up to 70% faster than traditional methods.

- Easy: Multiple high-resolution wireless targets with a range of up to 100 ft provide live alignment data, so alignment errors can be fixed without changing the setup.

- Accurate: Precision laser planes have a flatness of 2 arc seconds (.00012 in/ft or 0.01 mm/m) in a 180º/360º sweep and 1 arc second (.00006 in/ft or 0.005 mm/m) in a 90º sweep.

- Versatile: Depending on the laser plane configuration, the system is ideal for virtually all roll machinery; plus machining centers, gantries, roll forming machines and many other applications.

- Smart: Powerful Windows-based alignment software, combined with advanced wireless interfaces, makes collecting and analyzing alignment data fast and easy.