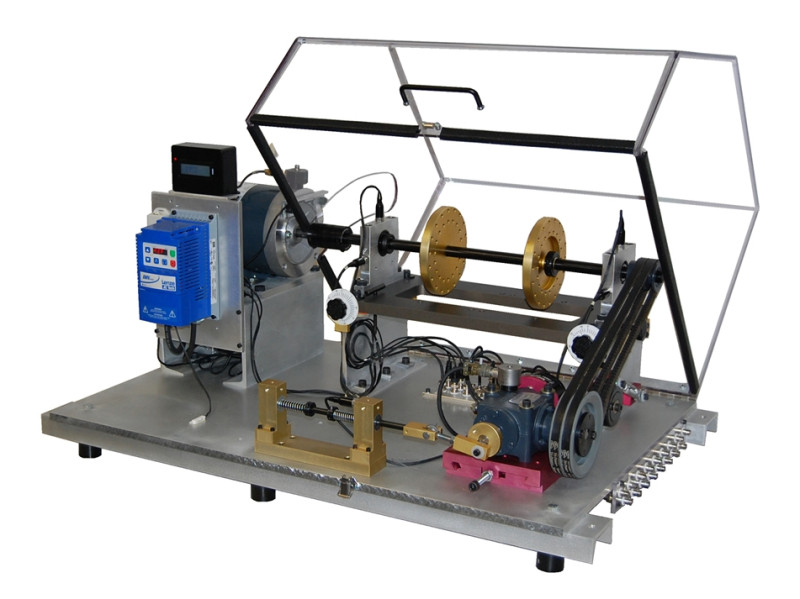

Machinery Fault Simulator (MFS)

The Best Tool Available for Learning Machinery Diagnosis

Description:

To gain an in-depth understanding of different vibration signatures, controlled experiments on a device that emulates real world machinery are needed. While analysis of a single machinery fault may be beneficial, there are many occasions when the analysis of the interaction between dynamic stiffness, resonance, and speed is essential in order to gain an understanding of real world vibration spectra. With the MFS, the expertise required to diagnose industrial machinery problems in well controlled experiments can be developed and enhanced. With a plant running at full production, it is virtually impractical to gain an understanding of the kinetics and dynamics of machinery without adversely affecting production and profits: The MFS enables offline training and experimentation which in turn will minimize production downtime.

-

Features

Features

• Simple methods for introducing controlled and calibrated faults.

• Study the vibration spectra of common faults, learn fault signatures and validate rules provided in training courses.

• Bench top machine for hands-on training and skill sharpening.

• Learn machine condition monitoring and predictive maintenance.

• Manual with exercises for individually paced study.

• Modular, versatile, robust, and comprehensive.

• Simultaneous reciprocating and rotating mechanisms.

• Learn resonance, variable speed, gearbox, and belt drive diagnostics.

• Learn to determine vibration transmission path and perform root-cause analysis.

• Study correlation among vibration, motor current, and noise spectra.

• Model rotor dynamics and its effects on fault signatures.

• Validate balancing procedures above and below the first critical resonance.

Smart Design Makes the Simulator Robust and Easy to UseThe MFS is designed to be both versatile and easy to operate. The simulator is constructed with a split bracket bearing housing, a sliding shaft, rotors with split collar ends, couplings, pulleys, a multiple belt tensioning and gearbox mounting mechanism, and reciprocating system; all of which are designed to be easily removed and replaced between various experiments.

The MFS is designed to be both versatile and easy to operate. The simulator is constructed with a split bracket bearing housing, a sliding shaft, rotors with split collar ends, couplings, pulleys, a multiple belt tensioning and gearbox mounting mechanism, and reciprocating system; all of which are designed to be easily removed and replaced between various experiments.

The Machinery Fault Simulator (MFS) is our most popular model, having a larger baseplate and a more powerful motor. Compared to the MFS-Lite, it adds capabilities to study machinery defects found in gearboxes, belt drives, reciprocating mechanisms, induction motors, pumps, and compressors.

-

Applications

The Best Tool Available for Learning Machinery Diagnosis

To gain an in-depth understanding of different vibration signatures, controlled experiments on a device that emulates real world machinery are needed. While analysis of a single machinery fault may be beneficial, there are many occasions when the analysis of the interaction between dynamic stiffness, resonance, and speed is essential in order to gain an understanding of real world vibration spectra. With the MFS, the expertise required to diagnose industrial machinery problems in well controlled experiments can be developed and enhanced. With a plant running at full production, it is virtually impractical to gain an understanding of the kinetics and dynamics of machinery without adversely affecting production and profits: The MFS enables offline training and experimentation which in turn will minimize production downtime.

Applications

• Balance training

• Shaft alignment training

• Alignment system assessment

• Coupling studies

• Bearing faults and load effects

• “Cocked” rotor

• Eccentric rotor

• Resonance studies

• Sleeve bearing studies

• Belt drive performance

• Mechanical rub

• Gearbox fault studies

• Reciprocating mechanism studies

• Foundation studies

• Signal processing techniques

• Variable speed/load effects

• Motor current analysis

• Rotor dynamics

• Operating deflection shape and modal analysis

• Optimize sensor mounting

• Sensor types (accelerometer, proximity probes, etc.)

• Vibration training

• Analyst certification

• Customized test bed for rotor dynamics studies and demonstrations

-

Specifications

Electrical Motor

3 Phase, 1 HP motor, pre-wired self-aligning mounting system for easy installation/removal Drive 1 HP variable frequency AC drive with multi-featured front panel programmable controller RPM Range

0 to 6000 rpm (short duration) variable speed Current Measurement

Power leads accessible for current measurements Tachometer Built-in tachometer with LCD display and one pulse per revolution analog TTL output for DAQ purposes Voltage 115/230 VAC, Single phase, 60/50 Hz Mechanical

Shaft Diameter

3/4″ diameter; Turned, Ground, & Polished (TGP) steel Bearing Two sealed rolling element in aluminum horizontally split bracket housing for easy changes, tapped for transducer mount. Bearing mounts can be mounted in five different position for variable rotor span Rotor Base

18″ long, completely movable using jack bolts for easy horizontal misalignment and standard shims for vertical misalignment. Pinned for easy realignment. Rotors Two 6″ aluminum with 36 threaded holes at 10 degree intervals for introducing unbalance Belt Mechanism

Two double groove “V” belt with one set screw mounting and one bush/key mounting. Positive displacement lever with turnbuckle plus adjustable gearbox platform Gearbox and Brake

Accessible three-way straight cut bevel gearbox with 1.5:1 ratio (20 gear input). Manually adjustable magnetic brake 0.5 – 10 lb.-in Reciprocating Mechanism

Adjustable spring engagement timing and two stroke settings.

Centrifugal Pump

1/2 HP, 27psi at 0gpm, 25gpm at 0psi with water at 4000rpm Reciprocating Compressor

1/2 HP, 2.6cfm, 120psi belt driven with 5-gallon air tank

Instrumentation Connectors

16 BNC connector plate under the rotor base linked to BNC connector panel mounted on the edge for the base plate for direct connection to data collectors

Safety Cover

Lockable clear, impact resistant hinged plastic cover with motor interlock switch to shut down motor when cover is raised

Foundation 1/2″ die cast aluminum base, base stiffener and eight rubber isolators Physical Weight

Approximately 130 lb Dimensions L=39″ (100cm), W=25″ (63cm) , H=21″ (53cm) -

Basic MFS

Basic Machinery Fault Simulator System includes:

• 1 HP variable frequency AC drive with multi-featured front panel programmable controller

• 3 Phase, 1 HP motor, pre-wired self-aligning mounting system for easy installation/removal

• Built-in tachometer with LCD display and one pulse per revolution analog TTL output for DAQ purposes

• Split bracket bearing housings

• 18″ rotor deck with five mounting positions for shaft span reconfiguration

• Two rolling element ball bearings with squeeze lock type

• Vibration isolators mounts and base stiffener

• Two balance rotors with two rows of holes

• Alignment system with calibrated reference dials and jack bolts

• One 3/4″ TGP straight steel shaft

• 16 BNC connector plate under the rotor base linked to BNC connector panel mounted on the edge for the base plate for direct connection to data collectors

• Power leads accessible for current measurements.

• Impact resistant clear safety cover with safety interlock

• Balance weight kit

• Allen wrench set

• 24V Power supply

• Cover support

• Comprehensive operations manual -

Packages

High Value Combination Packages

The MFS provides a basic setup for performing experiments and learning vibration signatures of different machine malfunctions. However, a detailed investigation of particular and more advance vibration phenomena or machinery fault will require additional attachments and fixtures which are available through optional kits. Depending on the package selected, you get a 6% to 12% discount over separately purchased items.

Package # 1 :

Basic MFS+ Kits for in-depth studies of alignment, balancing and resonance issues

Package # 2 :

Basic MFS+ Kits in-depth studies of alignment, balancing, resonance, and bearing defects issues

Package # 3 :

Basic MFS+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, and gearbox & belt drive issues

Package # 4 :

Basic MFS+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, gearbox & belt drive fault, reciprocating mechanism, mechanical rub, shaft/rotor crack and damping issues

Package # 5F :

Basic MFS+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, gearbox and belt drive fault, reciprocating mechanism, mechanical rub, shaft crack, damping, and fan issues

Package # 5P :

Basic MFS+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, gearbox and belt drive fault, reciprocating mechanism, mechanical rub, shaft crack, damping, and pump issues

Package # 5C :

Basic MFS+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, gearbox and belt drive fault, reciprocating mechanism, mechanical rub, shaft crack, damping, and reciprocating compressor issues

Package # 5M :

Basic MFS+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, gearbox & belt drive fault, reciprocating mechanism, mechanical rub, shaft crack, damping, and induction motor electro-mechanical defects issues

Package # 6 :

Basic MFS+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, gearbox & belt drive fault, reciprocating mechanism, mechanical rub, shaft crack, damping, induction motor electro-mechanical defects, pump, fan, and reciprocrating compressor issues

Package # 7 :

Basic MFS+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, gearbox and belt drive fault, reciprocating mechanism, mechanical rub, shaft crack, damping, induction motor electro-mechanical defects, pump, fan, and reciprocrating compressor issues; plus PC operation, shaft alignment kit and bearing loader with force transducer

Package # 8 :

Basic MFS+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, gearbox & belt drive fault, reciprocating mechanism, mechanical rub, shaft crack, damping, induction motor electro-mechanical defects, pump, fan, and reciprocrating compressor issues plus PC operation, shaft alignment kit, tri-axial force measurement of both bearing supports, bearing loader issues; and extra set of direct drive mechanisms for an alternate loading of induction motor electro-mechanical defects