DFR Fingertip: Delay-Line Transducers

Description:

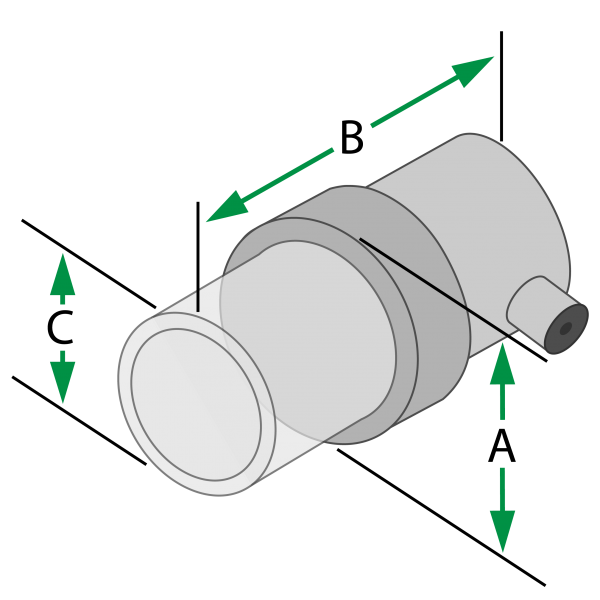

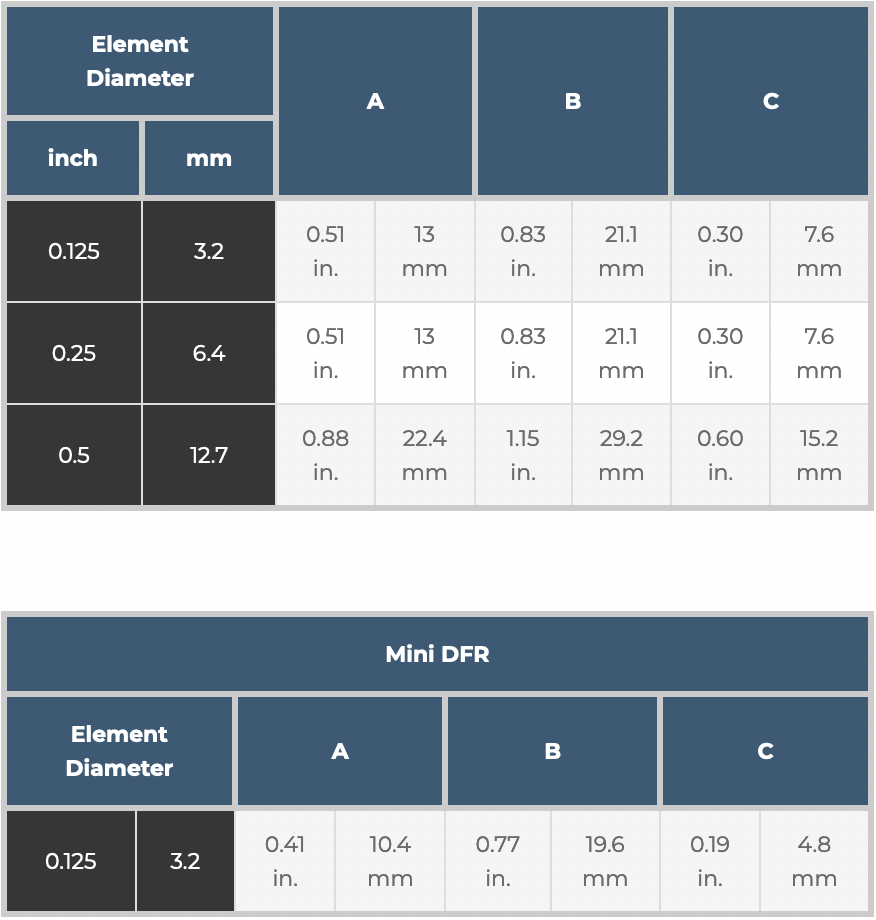

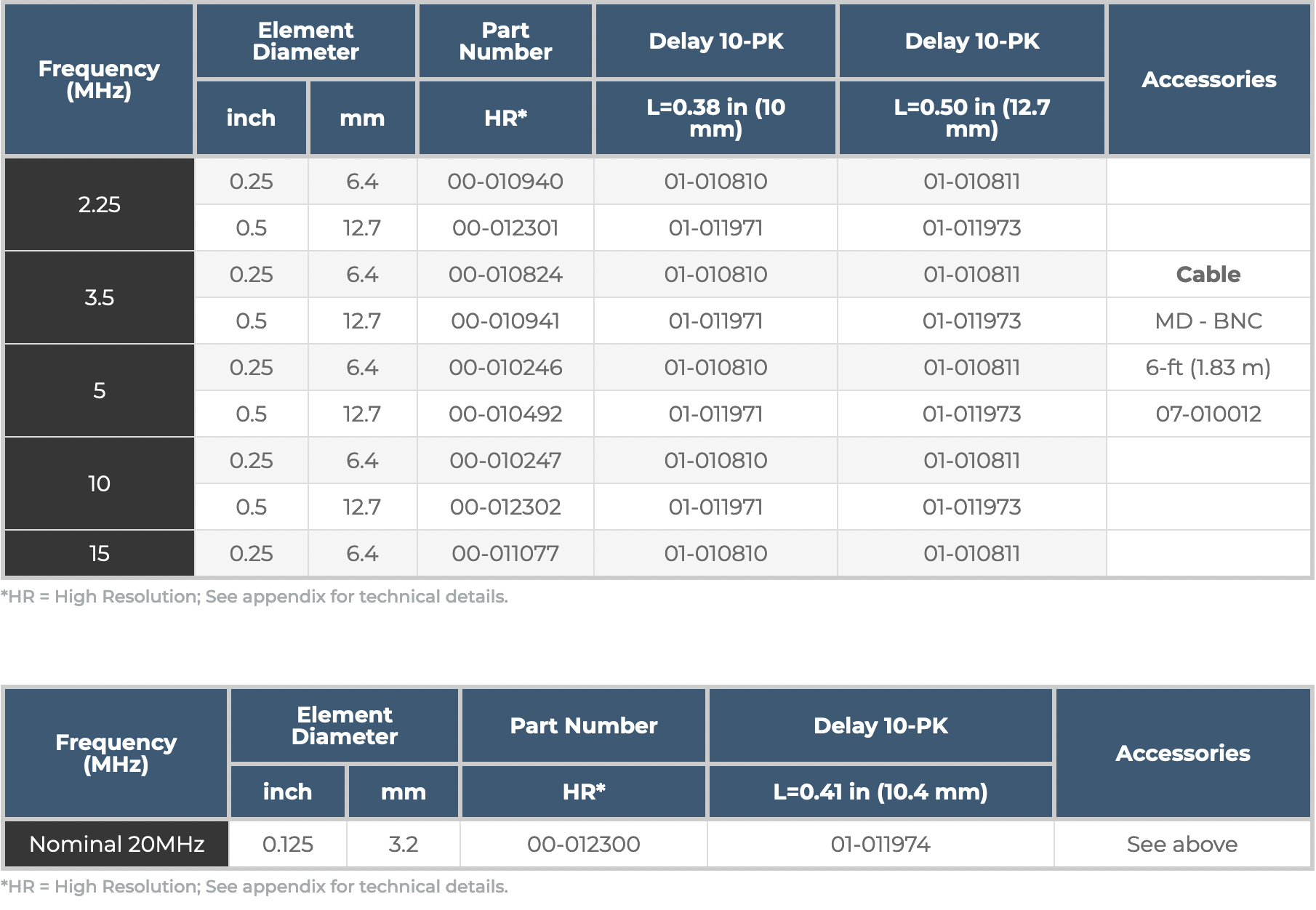

Model DFR are small-diameter delay-line transducers with side-mounted microdot connectors. Removable delay lines and highly damped piezoceramic elements enable measurement of very thin parts or detection of small near-surface flaws. Delay lines can be contoured for improved coupling to I.D. or O.D. curved parts. DFRs are available in HR Series* which are specialized applications requiring high resolution. Custom sizes and shapes also available upon request.

Delay-line contacts are single-element, longitudinal-wave (straight beam) transducers designed for detection of near-surface flaws and thickness measurement of thin-section materials. Replaceable delay lines (stand-offs) improve near-surface resolution and extend service life.

-

Descriptions

Typical Applications

- • Thickness Gauging

- • Plates

- • Bars & Pipes

- • Tanks

Key Benefits

- • Replaceable delay lines for extended transducer life

- • Can be used on higher temperature parts without damaging the transducer

- • Effective in small-flaw detection

- • Thickness Gauging on thin parts

Series

- *HR Series – High Resolution series of transducers are highly damped and recommended for applications where enhanced axial and near-surface resolution are more important. Generally includes thickness measurement and near-surface flaw detection. HR series have less sensitivity and the GP or C series with -6db frequency bandwidth of 50-100% range.

-

Specifications

Are single-element, longitudinal-wave (straight beam) transducers designed for detection of near-surface flaws and thickness measurement of thin-section materials. Replaceable delay lines (stand-offs) improve near-surface resolution and extend service life.

-

Downloads