Pencil Probe: Delay-Line Transducers

Description:

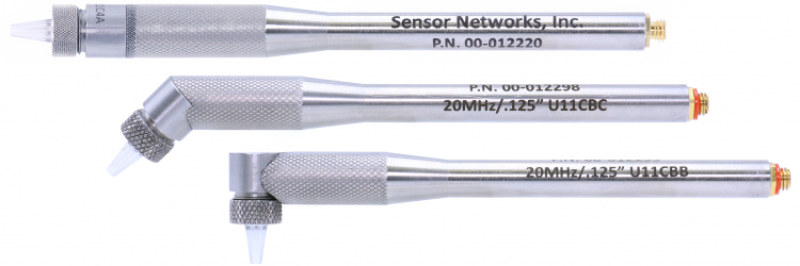

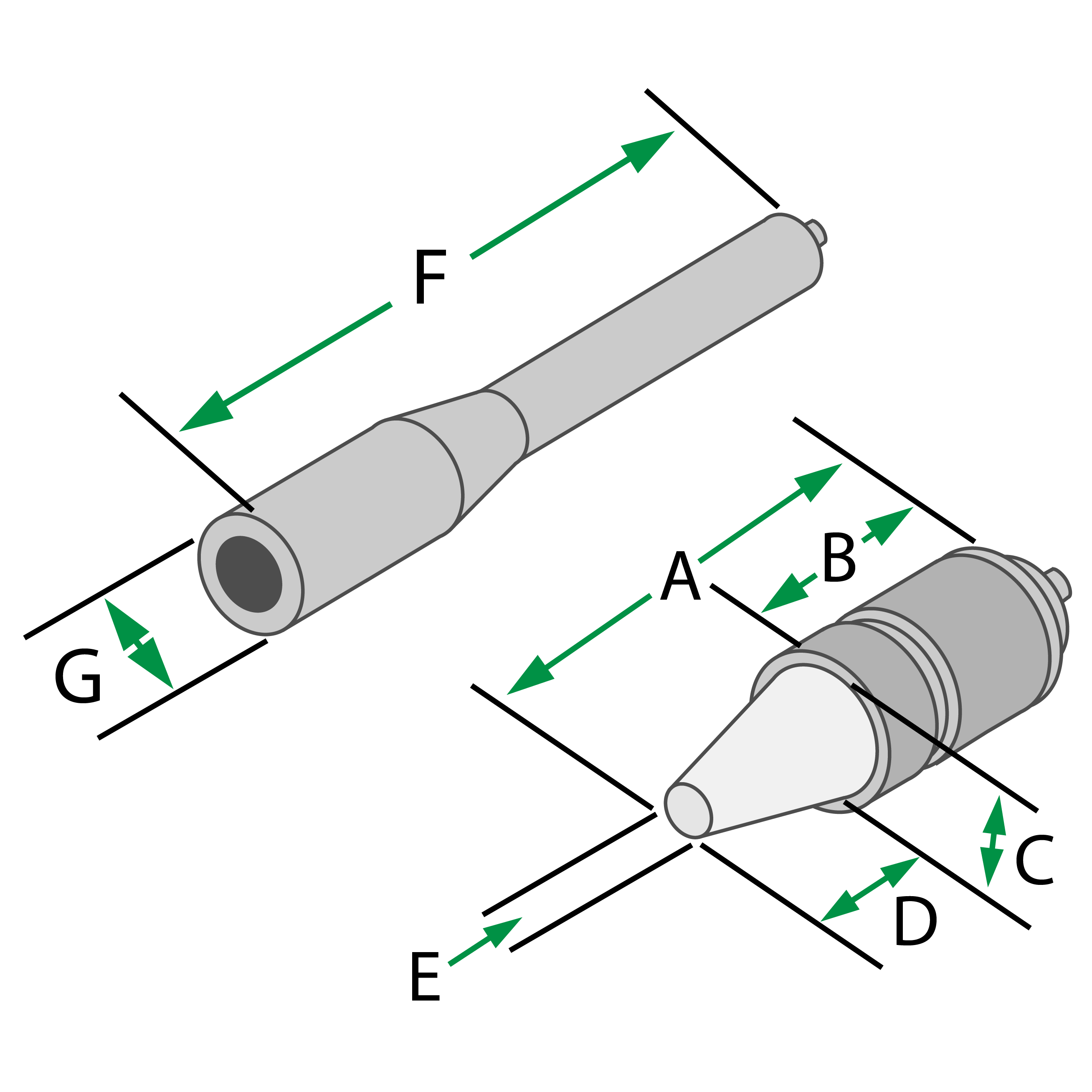

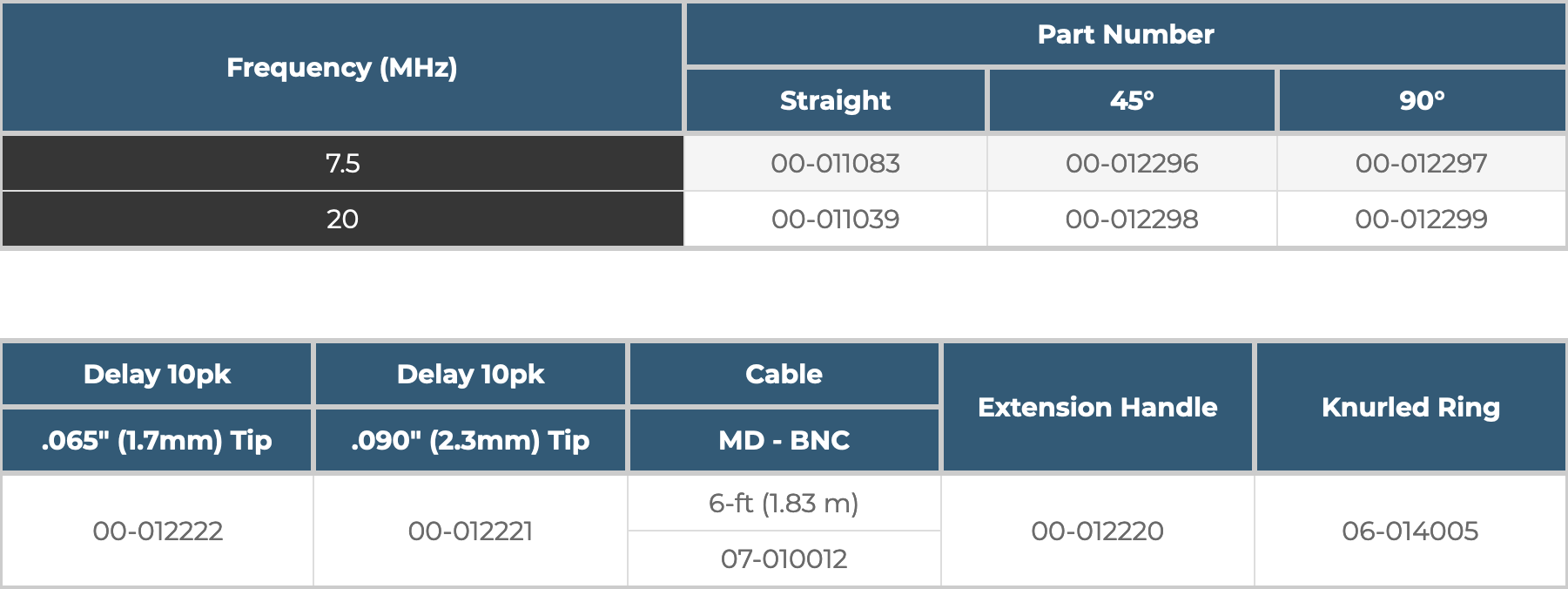

Pencil probes are designed for applications requiring a very small contact face such as curved turbine blades or thickness measurement from the inside of a pit. They can be used with most flaw detectors and precision thickness gauges. Interchangeable delay lines are tapered to tip diameters of 0.065 inch (1.7mm) and 0.090 inch (2.3mm). Replaceable delay lines are available in packs of 10. The straight model features a removable handle, which also allows it to be used as a fingertip probe. All models have microdot connectors.

Delay-line contacts are single-element, longitudinal-wave (straight beam) transducers designed for detection of near-surface flaws and thickness measurement of thin-section materials. Replaceable delay lines (stand-offs) improve near-surface resolution and extend service life.

-

Features

Typical Applications

- • Thickness Gauging

- • Plates

- • Thin Materials

- • Turbine blades

Key Benefits

- • Replaceable delay lines for extended transducer life

- • Can be used on higher temperature parts without damaging the transducer

- • Effective in small-flaw detection

- • Thickness gauging on thin parts

Series

- HR Series – High Resolution series of transducers are highly damped and recommended for applications where enhanced axial and near-surface resolution are more important. Generally includes thickness measurement and near-surface flaw detection. HR series have less sensitivity and the GP or C series with -6db frequency bandwidth of 50-100% range.

-

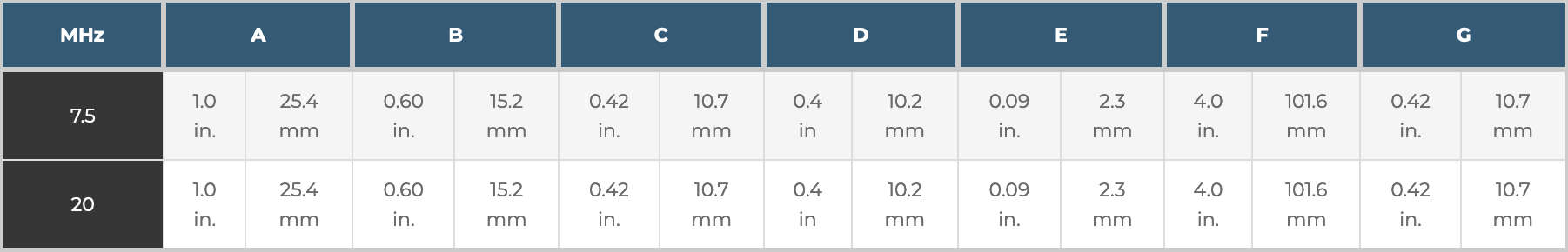

Specifications

Are single-element, longitudinal-wave (straight beam) transducers designed for detection of near-surface flaws and thickness measurement of thin-section materials. Replaceable delay lines (stand-offs) improve near-surface resolution and extend service life.

-

Downloads